There are two reasons for offering reconstruction of dehydration cycle, they are as follows:

Cyclohexane used in dehydration cycle features high corrosiveness which will require, to the Contractor’s point of view, to replace the equipment quite soon. Furthermore, based on many sources, cyclohexane is “a provoker” of oncological diseases.

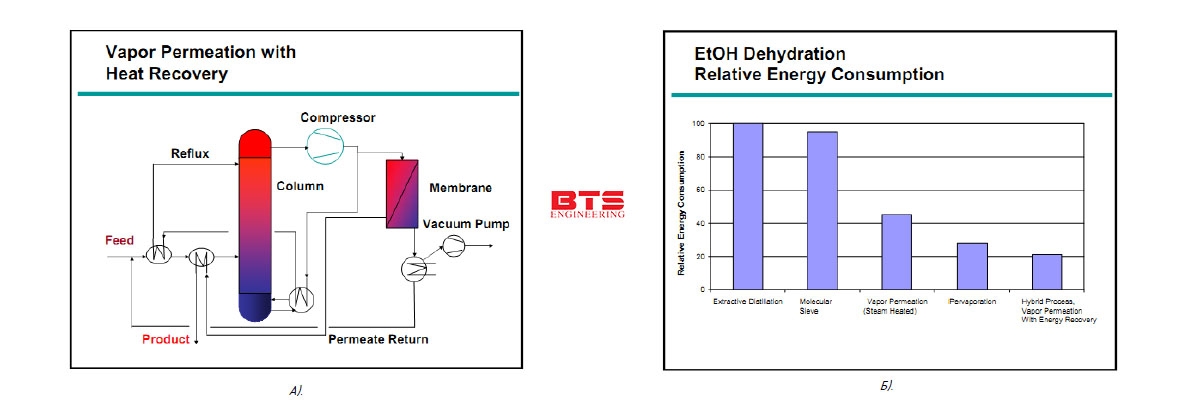

The offered technology of dehydration by PERVAPORATION MEMBRANES completely excludes cyclohexane using. Moreover, it consumes less technological heat, which allows making heat energy consumption by technological cycles more efficient.

Based on data [8], application of evaporation allows reducing consumption of technological heat energy by 2 times. In other words, the whole dehydration cycle of capacity of 100,000l/day will consume the same amount of heat energy in the form of steam as the existing dehydration cycle of capacity of 50,000l/day.

Basic scheme of measure implementation and comparative characteristics of heat energy consumption by different technological flow charts of dehydration based on the data [8] are shown in figure 7.2.2. The whole equipment for implementation of the measure offered can be installed in the existing productions areas.