If raw material with high moisture content (up to 18%) enters the enterprise, it is directed to the raw material drying unit equipped with a mining-type dryer. Drying unit is equipped with a gas burner. Approximate capacity of the drying unit is 3.0MW or 4 ton/h of evaporated moisture.

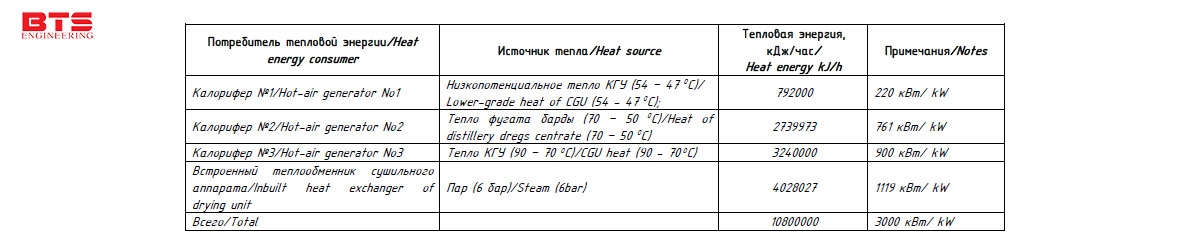

Aimed at decreasing of organic fuel consumption, re-equipping of drying unit is provided for operation from alternative heat source. Air, been initially warmed up in hot-air generator, is used as a drying agent. Heat of cogeneration unit, of boiler exhaust gases (operating from wooden “chips”), and steam are all used for air heating. Heat of a new boiler condensing economizer is transferred to hot-air generator by means of intermediate heat transfer agent. The hot-air generator, warmed up by heat of cogeneration unit (90 – 70 ОС) and the hot-air generator, heated by steam, are both additionally installed. Gas burner compensates probable lack of heat. Thermal capacity of hot-air generators of grain dryer is shown in Table 7.3.2.