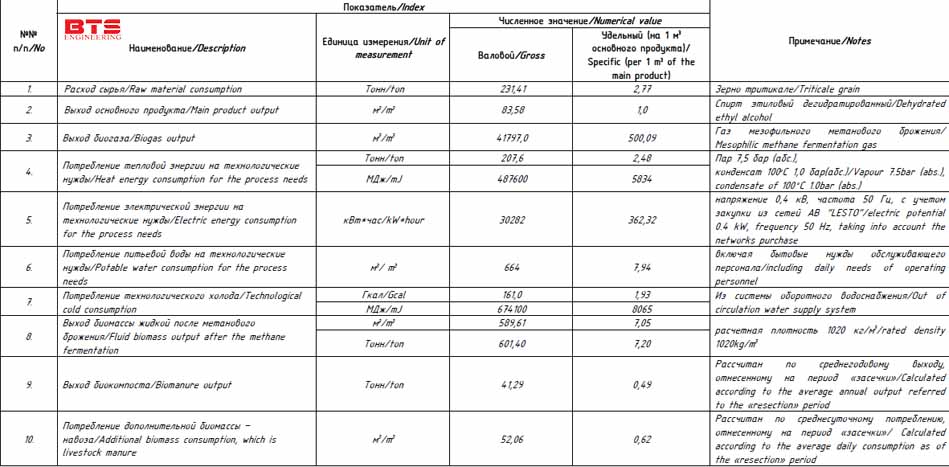

The base technological values of production as well as and energy consumption values have been “resected” in the period from 04.07 to 10.07.2014. The duration of «resection» was accepted as 36.75 hours, and defined by the time of pumping fermented alcohol mash out of В-204, В-206 and В-207 fermentation tanks.

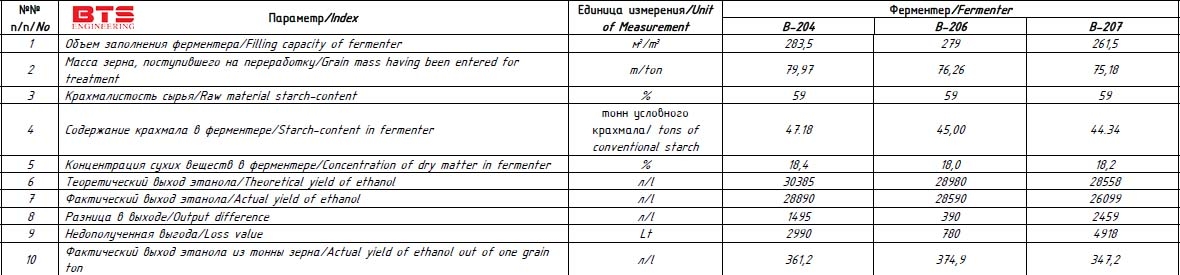

B-204 fermenter was considered to be a control one, it means that all technological processes in alcohol wort preparation were conducted by process methods operated by the plant. At the time of wort preparation in B-206 fermenter, a “full” set of new technological methods offered for implementation was used, namely:

Suggested process solutions were compared based on ethanol yield which enabled to formulate a number of technological measures to increase ethanol yield. Comparative «resection» results are shown in Tables 5.2.1 and 5.2.2. The «resection» results as the fulfillment of the 1st stage of engineering services provision of the energy and technology audit were discussed at the meeting between Contractor’s and Customer’s staff, held on the 10th of July 2014 in Pasvalys (Lithuania).

Starch content of raw material has been defined based on the results obtained at the Customer’s laboratory. Theoretical yield of ethanol of 644l per 1 ton of relative starch in triticale has been defined based on literature data [7]. Loss value based on the end price of 1l of ethanol is 2.00 Lt.